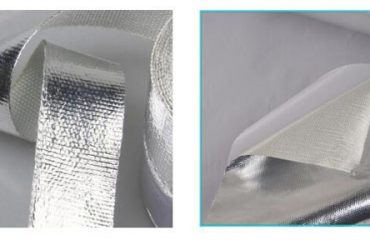

The thermal insulation sleeve is made of alkali-free glass fiber yarn woven into a tube, coated with organic high temperature resistant silicone resin and processed at high temperature. It has the properties of flame retardant, heat insulation, heat preservation, anti-electricity and softness. It is mainly used for cable insulation protection in high temperature places such as steel plants, smelters, glass plants, fire-fighting equipment, and large-scale transformer places.

Insulation casing performance:

High temperature resistance: The silicone structure on the surface of the casing contains both “organic groups” and “inorganic structures”. This special composition and molecular structure make it integrate the characteristics of organic substances and the functions of inorganic substances. Compared with other polymer materials, its outstanding performance is high temperature resistance. Therefore, the working temperature of the insulation sleeve is 260℃, which is suitable for most working conditions. It can withstand 5-10 minutes at a temperature of 1090℃, adapting to a short-term high temperature environment, and at a high temperature of 1650℃. It can withstand 15~30 seconds, prolonging the discovery and handling process of emergencies.

Thermal insulation performance: thermal insulation sleeve has better thermal stability than other polymer materials, radiation resistance and thermal insulation, preventing accidents, reducing energy consumption, and preventing the heat of the medium in the pipeline from being directly transferred to the surroundings The environment makes the temperature of the workshop too high, saving cooling costs.

Fire-resistant and flame-retardant performance: The insulation sleeve is woven with alkali-free glass fiber, and the surface silica gel is added with special materials such as appropriate flame retardants to make it have excellent flame retardancy. Even if a fire occurs, it can prevent the fire from spreading, and can still protect the internal pipelines intact for a long time, providing sufficient time for the rescue of important information such as data and materials.

Safety and environmental protection performance: The insulation sleeve is made of alkali-free glass fiber, with fine craftsmanship, less air and water pollution, and harmless to the human body. Unlike the medium-alkali glass fiber used by other manufacturers, it is harmful to the environment and the human body: the medium-alkali glass fiber composition contains a small amount of iron, aluminum, calcium, sodium and other oxides and bonded silica products. Long-term inhalation will cause The occurrence of pneumoconiosis.

The scope of application of the insulation sleeve is the high temperature areas of the electric power, chemical industry and other industries; the heating zone cables, fluid pipelines, feed quick change joints, rolling zone rollers, rolling mill cables, and oil pipes in the heating zone of metallurgical enterprises; sawing of peripheral cables, oil pipes and Connectors; ladle car cable coating and other fields.